Top Mistakes to Avoid When Using Silicone LED Profiles (and How to Fix Them)

Avoid Costly Errors and Get Perfect Lighting Every Time

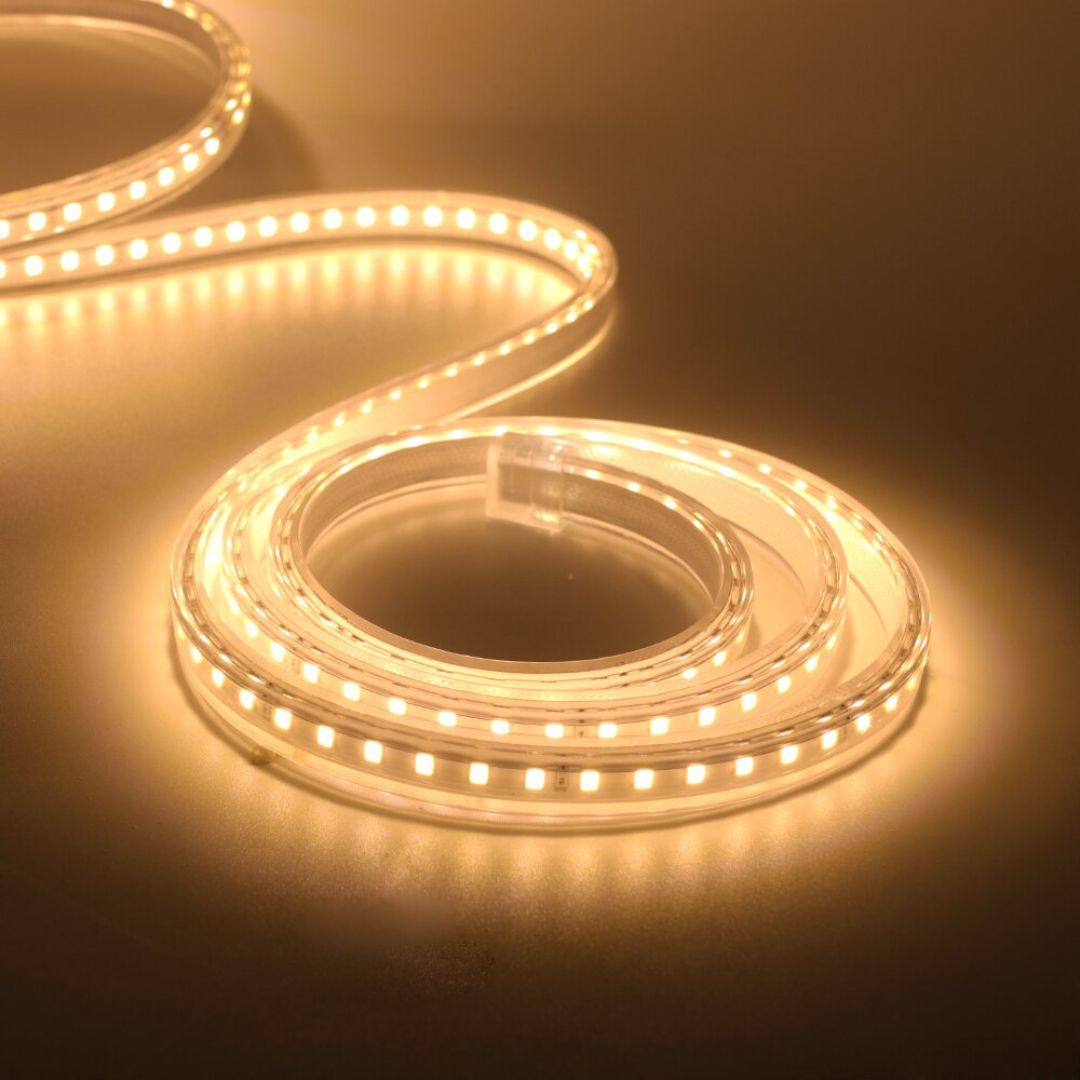

Flexible Silicone LED Profiles are engineered to make lighting sleek, durable, and elegant. But even the best materials can underperform if installed or used incorrectly. Whether you’re a lighting designer, installer, or DIY enthusiast, this guide outlines the most common mistakes and how to avoid or fix them — ensuring your lighting performs beautifully for years.

1. Choosing the Wrong Profile Type

One of the most frequent errors is selecting the wrong silicone profile view for the intended application.

|

Incorrect Choice |

Problem |

Correct Solution |

|

Using Side View profile for ceiling lighting |

Light diffusion looks uneven or misplaced |

Use Top View profiles for direct downward light |

|

Using Conceal View where visible edges matter |

Light appears hidden or dull |

Choose Top View for visibility |

|

Outdoor setup with non-waterproof profile |

Moisture ingress |

Use IP67 waterproof profiles (e.g., 16mm D-Shape, 20mm Round) |

💡 Tip: Always match profile direction (top, side, conceal) to the light path and environment.

2. Using the Wrong LED Strip Width

Each profile supports a specific LED strip width (e.g., 5mm–12mm). If you use a wider or narrower strip:

-

LEDs may not fit properly.

-

Light diffusion becomes inconsistent.

-

Overheating may occur.

✅ Always verify LED strip width before inserting into the profile.

|

Profile |

LED Strip Width (mm) |

|

8x8 |

5 |

|

10x10 |

5–6 |

|

13x13 |

5–8 |

|

16x16 |

5–12 |

|

20x20 |

5–15 |

3. Ignoring IP Ratings

Installing an indoor-rated profile outdoors is one of the fastest ways to ruin your LEDs.

-

IP20–IP40 = Indoor use only (dry areas)

-

IP67 = Waterproof, suitable for outdoor, kitchens, and bathrooms

🌧️ Always choose IP67-rated silicone profiles for outdoor signage, patios, or landscape lighting.

4. Over-Bending the Silicone Profile

Silicone is flexible — but it’s not indestructible. Bending profiles beyond their minimum radius causes:

-

Uneven light diffusion

-

Internal cracking

-

Weak spots or flickering LEDs

✅ Follow manufacturer guidelines:

-

Minimum bending radius: ≥ 40–60mm, depending on the profile.

-

For curves or creative shapes, use Side View or 360° Round profiles.

5. Skipping End Caps or Improper Sealing

Many installers overlook end caps, thinking they’re optional — they’re not.

End caps:

-

Prevent dust and water entry

-

Ensure light stays contained

-

Give a professional finish

Always seal both ends:

-

With holes: for power input

-

Without holes: for closed ends

Use neutral-cure silicone sealant for a long-lasting, waterproof bond.

6. Poor Surface Preparation

Mounting profiles on dusty, oily, or uneven surfaces leads to:

-

Weak adhesion

-

Falling profiles

-

Uneven alignment

✅ Always:

-

Clean surfaces with alcohol or a dry cloth.

-

Use mounting clips instead of glue for long installations.

-

Allow adhesives to cure for 24 hours before powering on LEDs.

7. Using Incorrect Power Supply or Voltage

Connecting a 12V LED strip to a 24V driver (or vice versa) can burn out LEDs instantly.

|

LED Strip Voltage |

Required Driver |

|

12V LED Strip |

12V DC Driver |

|

24V LED Strip |

24V DC Driver |

💡 Tip: Always check voltage printed on the LED strip or product packaging before connecting.

8. Not Testing Before Final Installation

One simple but critical step: always test your LED strips before sealing or mounting.

Skipping testing can result in:

-

Wasted materials

-

Hidden faulty connections

-

Difficult troubleshooting later

✅ Power on and test light diffusion, brightness, and color before you mount or seal your profile.

9. Using Harsh Cleaners

Silicone may resist UV and weathering, but harsh cleaning agents (like alcohol or thinner) can damage its optical clarity.

❌ Avoid: Alcohol-based wipes, ammonia sprays, or abrasives.

✅ Use: A soft damp microfiber cloth for gentle cleaning.

10. Forgetting Thermal Management

Even though silicone is flexible, it’s not a heat sink like aluminum.

So, for high-density LED strips (especially >14W/m), ensure:

-

Adequate ventilation behind profiles.

-

Use of 24V LEDs to reduce heat.

-

Avoid tightly enclosed spaces without airflow.

11. Cutting Without Measuring

Cutting first and measuring later often results in uneven gaps or mismatched corners.

✅ Always mark profiles precisely before cutting — a 1mm error can create visible misalignment in continuous runs.

12. Not Planning for Corners or Joints

Lighting lines that break at corners look unprofessional.

👉 Solution:

-

Use corner connectors or V-shape profiles for seamless 90° turns.

-

Plan continuous runs using Side View profiles for curves.

Summary: The Do’s and Don’ts

|

✅ Do’s |

❌ Don’ts |

|

Measure twice, cut once |

Bend beyond limits |

|

Match LED width to profile size |

Use indoor profiles outdoors |

|

Use mounting clips for better stability |

Skip end caps |

|

Test lights before sealing |

Overpower your LEDs |

|

Clean surfaces before mounting |

Use harsh cleaners |

Quick Troubleshooting Table

|

Issue |

Possible Cause |

Fix |

|

Flickering light |

Loose connection or wrong driver |

Check wiring and voltage |

|

Uneven glow |

LED strip twisted or bent |

Reinsert LED properly |

|

Water inside profile |

Poor sealing |

Reseal with silicone adhesive |

|

Profile falling off |

Weak surface adhesion |

Use clips or better adhesive |

|

Yellowing |

Non-UV-rated silicone |

Replace with UV-resistant profile |

FAQs

Q1. Can I bend all silicone LED profiles freely?

No. Each profile has a minimum bending radius. Use Side View or 360° profiles for curves.

Q2. How do I prevent water entry in outdoor installations?

Use IP67-rated profiles with sealed end caps and waterproof connectors.

Q3. What happens if I use a 24V strip with a 12V driver?

It won’t light properly — always match voltages.

Q4. Can I fix a yellowed profile?

No, once yellowed it should be replaced with UV-stable silicone.

Q5. What’s the best profile for curved furniture edges?

Use Side View Flexible Silicone Profiles (8x17 or 12x20).

CTAs

⚡ Shop Genuine Silicone Profiles: Explore the Full Range →

🧠 Download Installation & Maintenance Guide

📞 Consult Our Experts: Get design assistance for architectural projects.

SEO Metadata

Title: Top Mistakes to Avoid When Using Silicone LED Profiles (And How to Fix Them)

Meta Description: Learn about common mistakes in silicone LED profile installation and how to fix them — from wrong profiles to poor sealing and voltage mismatches.