Silicone vs. Aluminum LED Profiles — Which One Is Right for Your Project?

A Complete Comparison Guide for Designers, Installers, and Lighting Professionals

When it comes to LED lighting projects, choosing the right LED profile can make all the difference in performance, aesthetics, and longevity. The two most common options are Silicone LED Profiles and Aluminum LED Profiles — each with unique benefits depending on your application.

This comprehensive guide will help you decide which one fits best for your next residential, commercial, or architectural lighting project.

1. Overview of LED Profiles

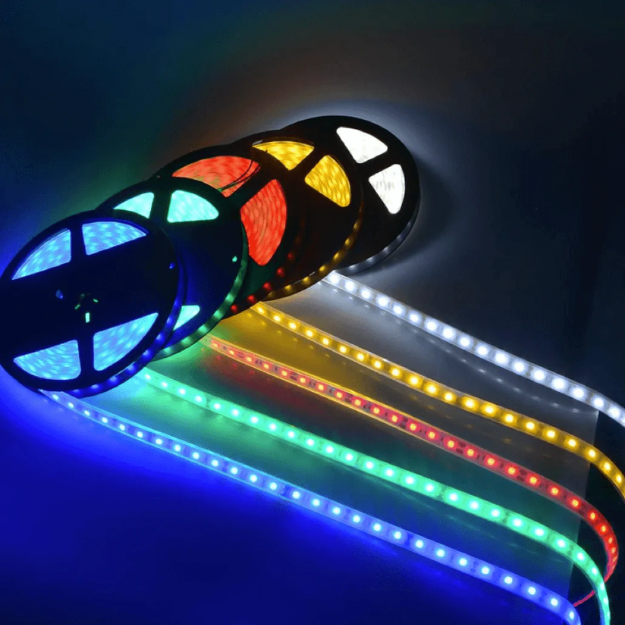

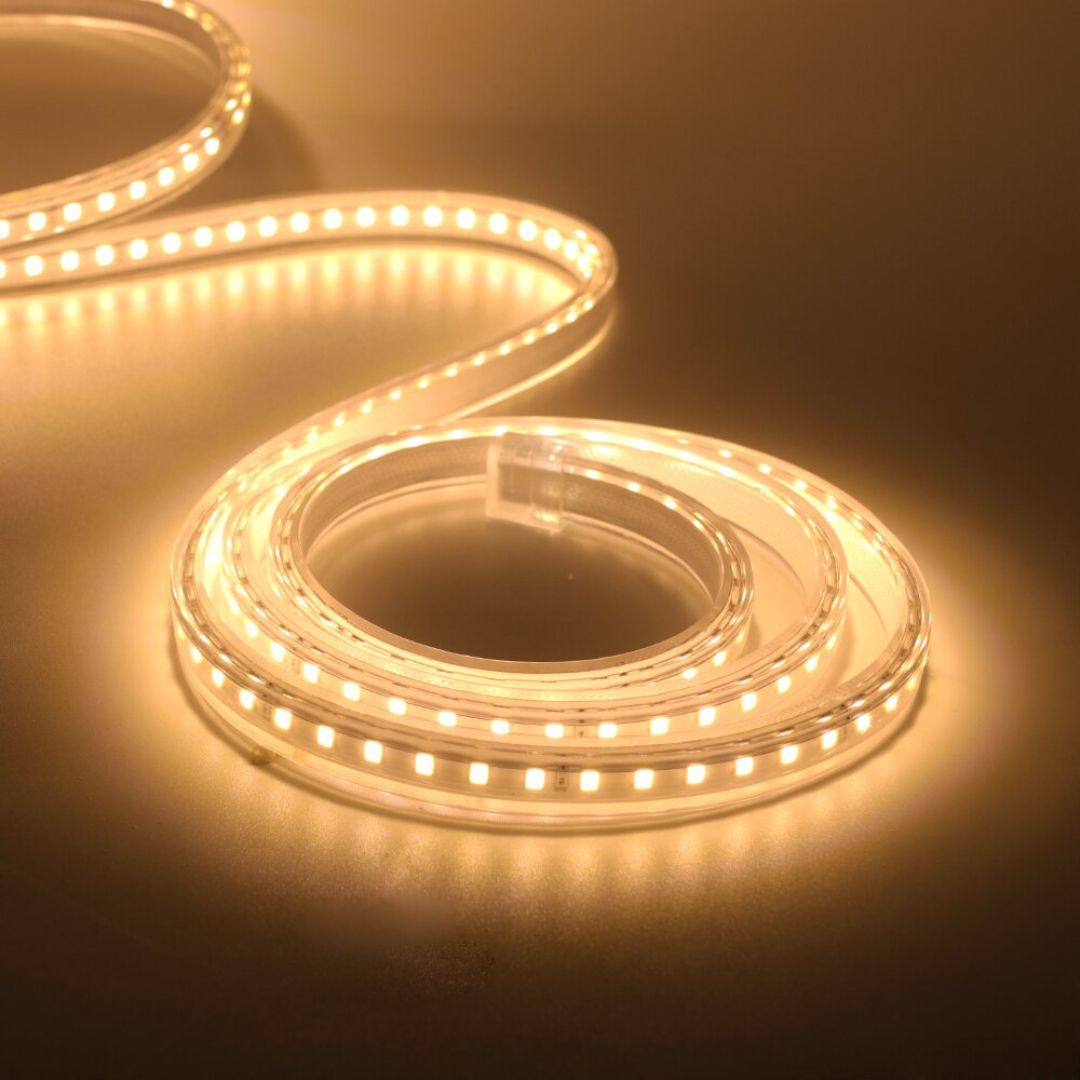

LED profiles (also called LED channels or housings) are used to protect LED strip lights, diffuse light evenly, and improve heat dissipation.

The two main types include:

-

Silicone LED Profiles (Flexible) — bendable, waterproof, and versatile.

-

Aluminum LED Profiles (Rigid) — strong, durable, and excellent for heat management.

Let’s compare them across key performance categories.

2. Flexibility and Design Freedom

|

Feature |

Silicone LED Profiles |

Aluminum LED Profiles |

|

Flexibility |

Highly flexible — can bend in multiple directions |

Rigid and non-bendable |

|

Shape Options |

Top view, side view, 360° round, D-shape, corner mount |

Linear, surface-mount, recessed, corner |

|

Best For |

Curves, arches, signage, creative designs |

Straight lines, clean architectural edges |

✅ Winner: Silicone LED Profiles

Ideal for designers who want freedom to create organic shapes and flowing light effects.

3. Durability and Weather Resistance

|

Parameter |

Silicone Profiles |

Aluminum Profiles |

|

UV Resistance |

Excellent |

Moderate |

|

Water Resistance |

IP67 Waterproof |

Non-waterproof (needs covers) |

|

Heat Resistance |

Up to 120°C |

Up to 150°C |

|

Yellowing Resistance |

High |

Not applicable |

|

Outdoor Use |

Ideal |

Limited |

✅ Winner: Silicone LED Profiles

Silicone models are purpose-built for outdoor, marine, and humid environments.

4. Heat Dissipation and Longevity

|

Feature |

Silicone |

Aluminum |

|

Heat Dissipation |

Moderate |

Excellent |

|

LED Lifespan |

High (with proper power supply) |

Very High |

|

Touch Safety |

Cool to touch |

Can get warm |

|

Recommended Use |

5mm–15mm LED strips, low–medium power |

High-power LED strips, long runs |

✅ Winner: Aluminum LED Profiles

For high-power industrial or large commercial setups, aluminum still offers superior thermal control.

5. Light Diffusion Quality

|

Aspect |

Silicone |

Aluminum |

|

Diffusion Type |

Soft, uniform, no glare |

Diffused cover (depends on design) |

|

Neon-like Glow |

Yes |

No |

|

Seamless Light Effect |

Excellent |

Moderate |

|

Hotspot Visibility |

None |

Visible in some cases |

✅ Winner: Silicone LED Profiles

Silicone’s elasticity allows seamless neon-like diffusion — ideal for ambient or decorative lighting.

6. Installation and Handling

|

Factor |

Silicone Profiles |

Aluminum Profiles |

|

Installation |

Easy, flexible fit |

Needs screws, mounts |

|

Cutting |

Scissors or blade |

Requires saw or cutter |

|

Weight |

Lightweight |

Heavier |

|

Mounting Accessories |

End caps, clips, glue |

Screws, diffusers, brackets |

✅ Winner: Silicone LED Profiles

Easier to work with, especially for DIY users and interior designers.

7. Aesthetic and Application Variety

|

Application |

Silicone Profiles |

Aluminum Profiles |

|

Cove Lighting |

✔️ |

✔️ |

|

Furniture & Kitchen |

✔️ |

✔️ |

|

Outdoor Facades |

✔️ |

❌ |

|

Signage & Displays |

✔️ |

❌ |

|

Industrial Spaces |

❌ |

✔️ |

|

Retail & Commercial |

✔️ |

✔️ |

✅ Winner: Both — depends on your project type.

8. Eco-Friendliness and Safety

Silicone profiles are non-toxic, UV-free, and recyclable, whereas aluminum profiles are recyclable but energy-intensive to produce.

✅ Winner: Silicone LED Profiles

Environmentally safer and more sustainable for long-term projects.

9. Cost Comparison

|

Aspect |

Silicone |

Aluminum |

|

Material Cost |

Slightly higher |

Moderate |

|

Installation Cost |

Lower |

Higher |

|

Maintenance Cost |

Minimal |

Moderate |

|

Lifetime Value |

Excellent |

Excellent |

✅ Winner: Tie

While aluminum may have a lower upfront cost, silicone offers better value in versatile, waterproof, and design-heavy projects.

10. Final Verdict — Which One Should You Choose?

|

Project Type |

Recommended Profile Type |

|

Outdoor façade or signage |

Silicone LED Profile |

|

Architectural interiors |

Either |

|

Modular kitchen or furniture |

Silicone (Top/Side View) |

|

Industrial high-heat areas |

Aluminum |

|

Curved design or creative display |

Silicone |

|

Linear office lighting |

Aluminum |

In Summary

|

Criteria |

Best Performer |

|

Flexibility |

Silicone |

|

Heat Dissipation |

Aluminum |

|

Waterproofing |

Silicone |

|

Outdoor Durability |

Silicone |

|

Linear Installations |

Aluminum |

|

Ease of Installation |

Silicone |

|

Cost Efficiency |

Tie |

🏆 Winner: Flexible Silicone LED Profiles — for 80% of architectural and interior applications.

FAQs

Q1. Are silicone profiles a direct replacement for aluminum profiles?

Yes, in most cases — except for very high-heat industrial setups.

Q2. Which lasts longer — silicone or aluminum?

Both can last 6–8 years with proper care, but silicone is better outdoors.

Q3. Do silicone profiles overheat easily?

No, but they’re best used with medium-power LED strips (5mm–15mm width).

Q4. Can I mix both in one project?

Absolutely — use silicone for curves and outdoor runs, and aluminum for straight indoor lines.

Q5. Do aluminum profiles look more premium?

Not necessarily. Modern silicone profiles offer seamless neon-like effects and high-end finish.

CTAs

💡 Shop Premium Flexible Silicone LED Profiles → View Collection

🏗️ Need Help Choosing? Get expert advice from our lighting consultants.

📘 Compare All Profile Sizes → Download Product Comparison Sheet (PDF)

SEO Metadata

Title: Silicone vs. Aluminum LED Profiles — Complete Comparison Guide

Meta Description: Discover key differences between silicone and aluminum LED profiles. Compare flexibility, waterproofing, heat management, and ideal use cases for your lighting project.